Specialist Fuel Oil System/ Fuel Transfer System/ Diesel Oil System

Engineering, Construction and Testing/Commissioning of Specialist Fuel Oil System/ Fuel Transfer System/ Diesel Oil System for Critical Facilities.

Engineering Procurement Construction (EPC), Testing & Commissioning of Petroleum Storage & Distribution.

Main Fuel Storage and Day Fuel Tanks

- Single & Double Wall Fuel Storage Tank with Interstitial Leak Detection.

Automatic Fuel Oil Transfer Pump Sets

- Factory Packaged, Pre-engineered, Pre-wired, Pre-plumbed System

Flexible System Controller & Tank Monitoring

- Explosion Proof Control Panels

Fuel Fill Cabinets & Fuel Filtration Systems

Double Containment Fuel Pipes with Interstitial Leak Detection.

Electronic Grounding System.

Praxis Technical Services LLC offers a wide variety of fuel oil system components designed to meet the unique requirements of our fuel oil customers. We Supply customized quality

We are experts with fuel oil transfer pump systems including the application, design, and fabrication of the total system. Systems include Packaged Transfer Pump Skids, Day tanks, flow control manifolds, filtration (polishing) systems and fuel oil handling accessories, Drive Systems, Control & Automation Systems, Control Panels, Metering / Dispensing /Leak Detection /Cathodic Protection Systems and Efficient Fuel Management System. The major brands the organization represents include self-priming pumps from Major Pump & Motor Manufactures in the world.

The organization focuses on pumps, pumping systems, drives and related instrumentation and equipment for various applications in the field of water, wastewater, sewage, industrial, petroleum, process and oil field sectors.

The company also offers turnkey solutions to the fuel storage and distribution sector especially pumps, flow meters, loading arms and related instrumentation equipment.

Capabilities

Custom Engineering : Praxis Technical Services LLC is a specialist provider of advanced fuel transfer systems for commercial, industrial, Defense Location and residential complexes. We provide the full scope of services right from advanced technologies to innovative engineering, to highly professional installation and commissioning. We work with our client’s engineers, consultants, regulatory agencies, local subcontractors, and world-wide suppliers to deliver high quality systems and customized solutions.

Single Source Responsibility :

Incorporating a total systems approach to fuel management, each job is treated as a unique design project. Pumps are chosen to meet required flow and pressure criteria for the fuels being pumped. A control strategy is chosen to provide the desired degree of automation while assuring the highest levels of reliability. Monitoring and alarm points are selected to alert operations staff of any change in status. By combining pumps, day tanks, controls, level and leak monitoring into a single package, an optimized system with single source responsibility is assured. Praxis Technical Services LLC takes a total fuel system approach to your application requirements.

We provide the following:

Conceptual System Design : Because Praxis Technical Services LLC is involved in all types of systems. we can bring the “best in class” from many different applications. We can consult with you from the ground up on matching your needs with the proper system to handle your fuel oil needs that will provide a reliable cost effective solution. We understand that these systems may not be used often, but when they are called upon to work – they have to work flawlessly.

Detailed System Design and Sizing : Praxis Technical Services LLC can work with you to size the pumps to match your requirements, to size the piping to give you a cost effective installation and will perform suction and discharge calculations to make sure the system provides reliable service. As controls systems become more involved with these systems we will also help layout a system that will provide safe and reliable service and provide the informational needs of the facility. We can also work with the commissioning agent to layout the commissioning procedure customer for each installation.

Overall Project Management : Once a project is started we can help with management of that project throughout its lifetime. Praxis Technical Services LLC can help maintain the time schedule with is typically so important on these project. Steps that are critical are the submittal process, parts purchasing, assembly and testing, timely shipment, installation help for the contractors, startup, commissioning and training.

Manufacturing : The pump sets, day tanks and filtration systems are manufactured to the latest industry standards. Control panels are manufactured to UL508 standards and are fully tested at the factory.

Startup : Once installed factory trained representatives will help with startup of the equipment. Typically they are also available for installation help where they will meet with the installers to makes sure the equipment is installed properly the first time eliminating costly and “time delay” rework at the job site.

Commissioning : Our equipment is designed to make commissioning easier. Our factory trained representatives will be available to help with commissioning.

Documentation : All system are fully documented with equipment drawings and electrical schematics. Sequence of Operation documents is also included for all the control equipment.

Training : After the system is installed, started up and commissioned our factory trained representatives are available for training.

Life Cycle Support : For the life of the product we are available for support. Typically these systems once installed and commissioned will require very little support, but if it comes up we are available to help with parts, field service, and design upgrade services. If you have a filtration system we will support your needs with replacement filters and chemical additives.

System Installation :

Building a new fueling facility or upgrading an existing location can be challenging for any company. The key to successful projects, completed on time and on budget, is working with a knowledgeable fuels systems partner who has a depth of capability and dedication to lasting relationships.

Our construction team is staffed with highly qualified and experienced personnel provide above and below ground storage tank installations, upgrades, repairs and removals.

Full Range of Systems and Solutions : Praxis Technical Services LLC offers a complete range of Fuel System modules.

Our scope includes :

- Tank Storage Systems, including single wall, double wall and dyked tanks for bulk storage and day tanks.

- Tank Fill Systems including overfill protection systems consisting of high level warnings, pump shutdown, and automatic valve closures.

- Fuel receiving pump units in simplex and duplex mode with advanced pump controls.

- Fuel Dispensing Systems with submersible fuel pumps with dispensers for petrol and diesel and required hoses, nozzles, safety breaks, and retractors.

- Advanced mechanical components and sensors including level transmitters, level switches, multi-level switches, flow switches, pressure switches, leak sensors, and temperature sensors.

- Containment piping for piping systems located underground or inside buildings.

- Loading Bays and Canopies for safe inspection and filling/dispensing of tanker trailers cars with top loading systems. Designing to commissioning

Our qualified engineers can offer the best solutions for the fuel transfer system with best logic for controls. P & ID, Piping isometric and other drawings are designed in house. Our stock of specialized material / gauges, sensors/ controllers and transmitters of diesel system is normally enough to meet the most requirements. Special design can also be done on request. Fuel tanks are fabricated to meet UL /API//BS Standard BS-EN 12285-2.2005. Rectangular and Cylindrical tanks up to 90,000 Liters in single and double wall construction are done to meet your requirements. All fuel transfer lines are compressed air tested to ensure free of leakages and ensure safe to operate after installation. Our experience list and major project references are available on request.

Praxis Technical Services LLC designs and executes complete fuel system including mechanical, electrical, and control components. We perform value engineering analysis of alternatives, and obtain all permits required for system installation. Praxis Technical Services LLC performs site installation work in all over UAE. We act as the sole source of responsibility, where fuel systems constitute a critical component of your project.

EQUIPMENT & PRODUCTS

Under Ground & Above Ground (Double Wall) Fuel Tanks

UL-142 single wall and double wall tanks with or without containment dikes are built to customer specifications and are the most economical and versatile above ground tanks available.

The tanks are designed and built to meet or exceed current industry, environmental and ¬re regulatory standards, and are in conformance with UL/ULC, SwRI, NFPA, UFC, API, ASME, or STI speciation and standards.

FUEL STORAGE - DAY TANK

The Day Tanks provide a local supply of distillate or diesel fuel for boilers, emergency generators or other stationary engine driven or oil fired equipment.

For mission critical applications such as emergency diesel generators and dual-fuel boilers, it is recommended that at least four hours worth of fuel is immediately available to the unit without activating transfer pumps.

DISPENSING UNITS

Our fuel dispenser solutions deliver proven reliability and profitability. Centering on quality and innovation, our fuel dispenser solutions are designed to deliver profitability for our customers today and tomorrow.

FUEL FORWARDING PUMP SYSTEM

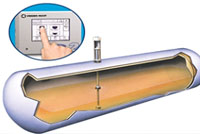

Automatic Fuel Oil Transfer Pump Set : The Automatic Fuel Oil Transfer Pump Set is a state of the art system duplex pump sequencing and monitoring system. This system includes automatic lag pump back-up features that improve fuel system availability and safety. The LCD display is used to monitor day tank and pump set status and alarms.

The Automatic Fuel Oil Transfer Pump Set is a factory packaged, pre-engineered, pre-wired and pre-plumbed system that includes pumps, industrial motors and accessories. These systems are shipped to the job site, requiring only external fluid and electrical connections ensuring undivided responsibility of delivering fuel at the selected flow.

FEATURES

- Loop or Day Tank Fuel Oil Transfer System

- Microprocessor Based Monitoring and Control with Automatic Lead/Lag Function

- Automatic Pump Prime and Suction Line Integrity Check

- Main Storage Tank Monitoring

- Automation System (BAS) Interface

- Alarm and Event Summaries

Fuel Filtration Systems : Model PF, Fuel Oil Filtration System - Self-contained, fully automatic systems remove water, suspended rust, dirt and other contaminants in order to maintain the quality and purity of stored diesel fuel. Multiple Stage Fuel Oil Dewatering and Cleaning Process.

Efficient Fuel Management System Panel (EFMS): The control panels to control fuel oil level in day and bulk tanks using valves or run/standby Fuel Transfer Pump s, tank level alarms and controls to dump fuel to a dump tank in the event of a Fire.

Control Cabinet/ Panel is completely pre-wired, tested and delivered as an integrated system to insure job site reliability. System is designed to accomplish the control strategy as outlined. Control strategy is Microprocessor based and utilizes a PLC (Programmable Logic Controller).

If the control center is remotely mounted, the PLC shall communicate with the skid mounted pumping system containing remote I/O modules through a Network Interface Unit.

Fuel Management Control Panels:

Fuel Sentry Tank Gauge and Leak Detection System : The Fuel Tank Gauge and Leak Detection System is a remote reading, microprocessor based, tank gauge, with six intrinsically safe sensor inputs that can monitor one or, multiple tanks.

The Fuel Sentry Tank Gauge and Leak Detection System is designed for use with double wall tanks, vaulted tanks, single wall tanks with spill basins, and double wall piping. It is designed for use with all fuel oils , diesel, kerosene, jet, and most other petroleum products. Tank gauges are required by NFPA 30 Flammable and Combustible Liquids Code and NFPA 31 Standard for the Installation of Oil-Burning Equipment, and NFPA 110 Standard for Emergency and Standby Power Systems.

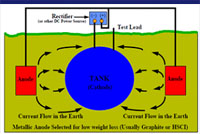

Fuel Tank & Pipe Line Corrossion/Cathodic Protection System :Praxis Technical Services LLC is capable to offer infrastructure protection and also provide proprietary technologies and services for the corrosion protection of steel pipelines and for sewer, water, energy and power and process piping systems, steel structures Steel storage tanks. We can provide equipment and control units, which prevent the loss of metal and the loss of coatings due to corrosion.

Fuel Oil Specialties